Fuel Additives for Coal-Operated Boilers

Improved efficiency and reduced slagging and corrosion in the boiler, through SENTROJETTM chemical injection into coal or bio-fuel fired boiler or furnace.

We provide a simple, flexible and cost-effective solution to problems arising from the combustion of coal, heavy fuel or bio-fuels.

Applicable for: coal-operated steam boilers, cement furnaces or any other coal or heavy-fuel operated equipment.

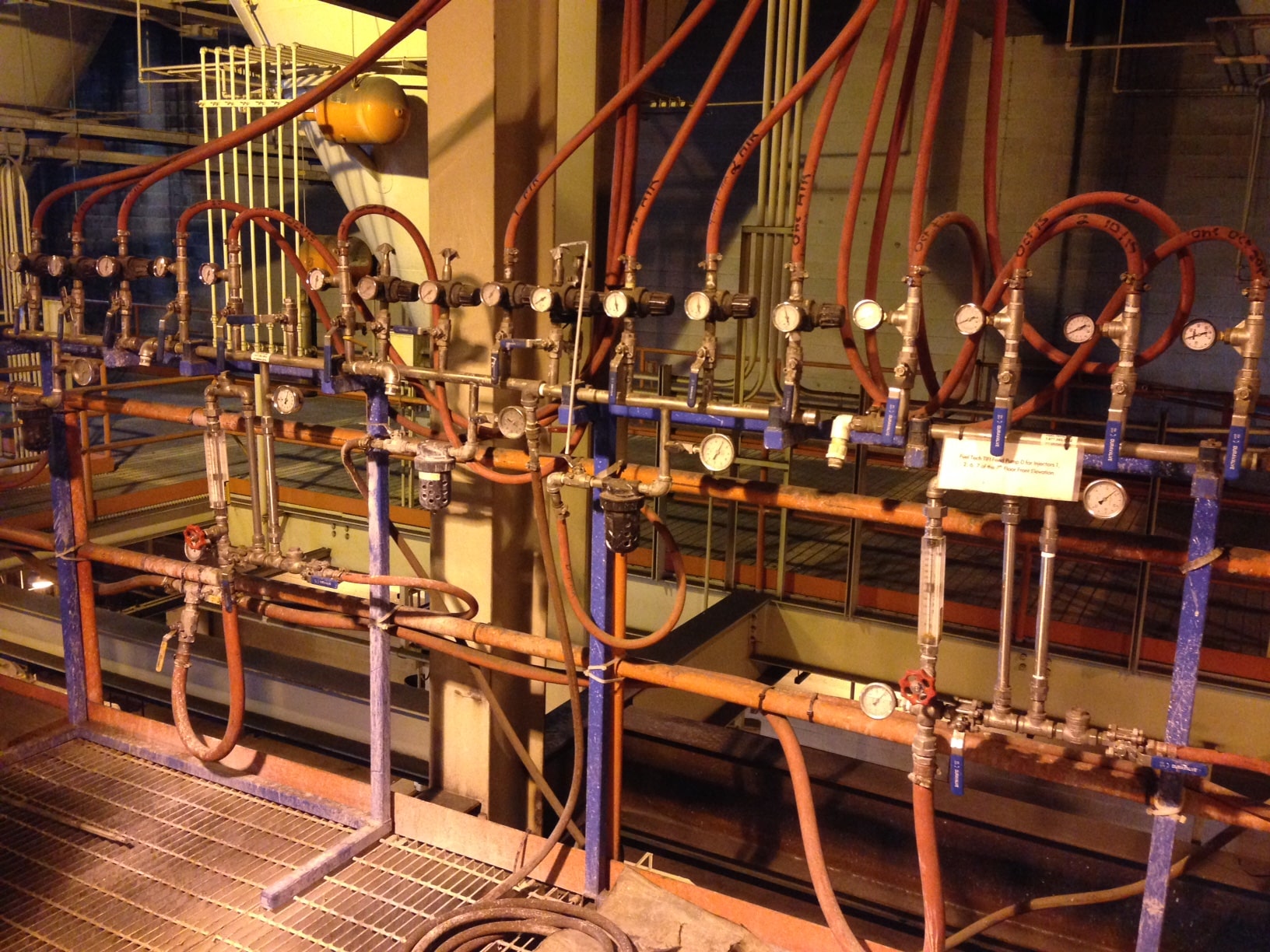

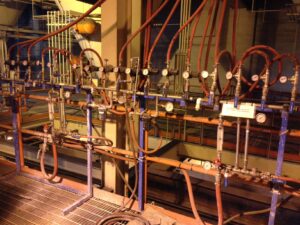

Our method is based on injecting SENTROJETTM slurry product on the coal belt (pre-combustion) or directly into the combustion chamber (post-combustion). This produces chemical reactions that oxidize, neutralize and convert residues from combustion, which would otherwise increase fouling, corrosion, and air pollution.

Reduces fouling, slagging and corrosion will immediately increase the thermal efficiency of the boiler or furnace, resulting:

- Reduced fuel consumption

- Save energy

- Reduced emissions/pollution

All SENTRO’s cleaning and inspection systems are the result of practical applications combined with continuous research and development.

Sentro Technologies USA, LLC

Online Dry Chemical Cleaning of Fin Fan Air Coolers, Furnaces, and Boilers | APR Acoustic Pulse Reflectometry Tube Inspection | Acoustic Emission Testing | Jacob's Sniffer 430 Leak Detection