Chemical Decontamination of Process Units

SENTRO Vapor-Phase Chemical Decontamination

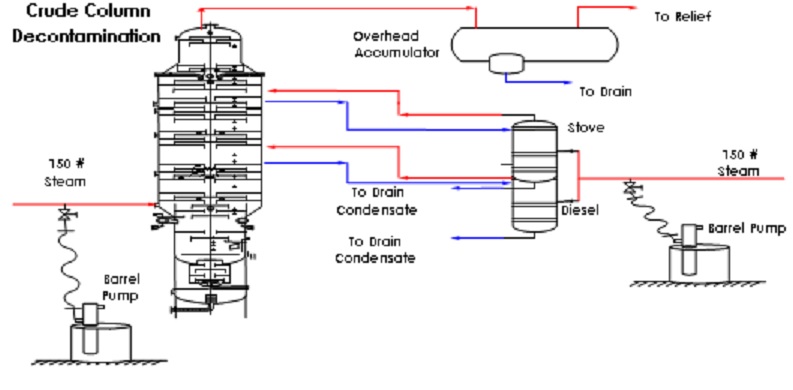

Application:

- Chemical injected into steam.

- Minimal changes in operational steam-out procedures.

- Continuous injection of fresh chemicals.

- Continuous monitoring of hydrocarbon / LEL / H2S / Benzene levels.

- De-oiling, degassing & Sulfide oxidation (no Pyrophorics).

- Applicable for Heavy Oil Units such as Atmospheric, Vacuum, Visbreaker, Desalter, etc.

- Applicable for a combination of furnace + tower bottom + overhead system (coolers, accumulator) + pump around / sidecuts, etc.

Advantages:

- Minimizes Down Time

- Reduces Steam Out Duration.

- Reduces Maintenance Activity Before and After Decontamination Process.

- Environmentally Friendly

- Biodegradable.

- Extremely Low Chemical Oxygen Demand (COD) Waste.

- Does not make Stable Emulsions.

- Minimizes the amount of waste generated.

- Effective

- Penetration and softening of heavy residuals and asphaltenes.

- Assures chemical contact and reduces the possibility of channeling.

- Will suspend Coke scale and particulates.

- Efficient

- Results are equal to a cascade or full circulation but with less effluent volume.

- Fewer mechanical connections and less maintenance time.

Set-up is simple, fast, and economical:

- Includes barrels, barrel pumps, ½” flexible hoses, and ¾” or 1” injection connections.

- (unlike liquid circulation –this application does not involve a tank, chemical blending, centrifugal pumps, heavy flexible hoses, temporary connections, large effluent volume to be treated, and more..)

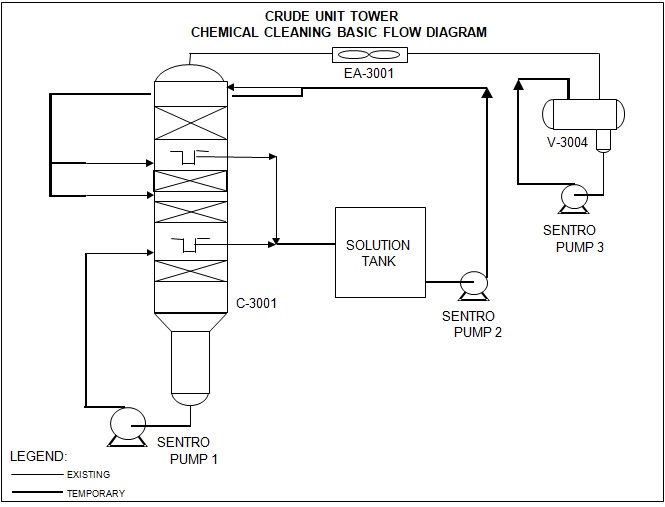

SENTRO Liquid-Phase Chemical Decontamination

Application:

- The process is safe and effective

- Removes heavy oil deposits, organic scale, coke, and polymers

- Non-hazardous and non-corrosive chemicals, in water-based chemical solution

- Compatible with the unit’s metallurgy

- Effluent is biodegradable and non-transport-regulated

- Inline 10 um filtration to capture solid particles

- Chemical solution can be heated by steam or by an external heat source

- Optional low-temperature circulation for limited-temperature applications

- Optional for a solvent-base non-aqueous chemical cleaning in specific applications

- Optional two-way circulation: direction of the circulation can either be against the process flow or with the process flow

Advantages:

- Environmentally Friendly

- Biodegradable

- Low Chemical Oxygen Demand (COD) Waste

- Does not make Stable Emulsions

- Effective

- Penetration and softening of heavy residuals and asphaltenes

- Assures chemical contact and reduces the possibility of channeling

- Will suspend and remove coke scale and particulates

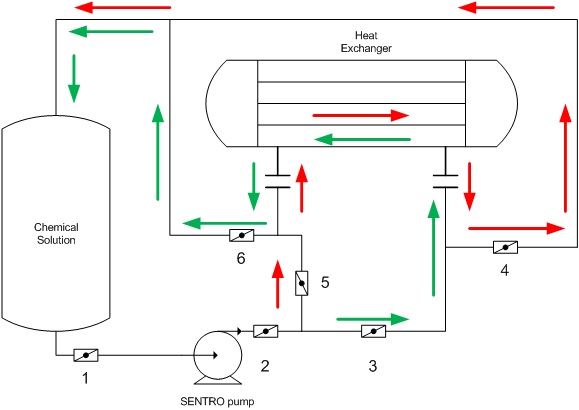

Optional: Boilout chemical decontamination for vessels

- The vessel is flooded and filled with chemicals and water

- Steam or an external heat source is added to heat the solution and agitate sludge or solids

- Covers all sludge layers and assures chemical contact

- Immediately reduces odor concerns

- Great application for storage vessels, overhead receivers and fuel gas KO drums

- Works well in vessels that have limited Tie-in locations or steam connections

- Allows fewer temperature restrictions

Pre-flush and Post-flash advantages

- Pre Flushing

- Helps reduce surface tension and remove free solids

- Penetration and softening of Atmospheric Residue

- Assures chemical contact of solids in packed sections and dead spots

- Post Flushing

- Assures chemical saturation and neutralization of pyrophoric in large packed sections

- Helps to carry out free solids

- Will rinse out residual chemicals and reduce the odor

- Oxidized rinse water helps with effluent disposal

Sentro Technologies USA, LLC

Online Dry Chemical Cleaning of Fin Fan Air Coolers, Furnaces, and Boilers | APR Acoustic Pulse Reflectometry Tube Inspection | Acoustic Emission Testing | Jacob's Sniffer 430 Leak Detection