On-Line dry chemical cleaning of Air Coolers

Case Studies – Online (in-process) dry chemical cleaning of Air Coolers

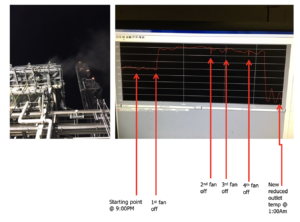

Forced-draft fans, night shift (TX, USA)

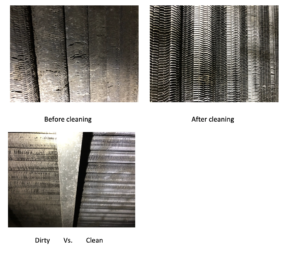

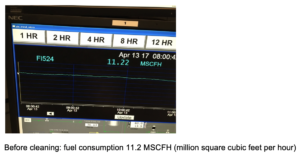

Induced-draft fans, steel fins (OH, USA)

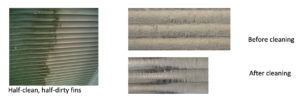

Induced-draft fans, aluminum fins (CA, USA)

Induced-draft fans, aluminum fins (MT, USA)

Sorry for taking some long to give you this information. Here are the functional location of the fin fans.#4 AVGO- SouthWest-004-0042-BB, North west 004-0043-AB, (S)East 004-0042-BA, (N)east 004-0042-AB. LVGO- (N)west 004-40-1A, 004-0040-1B, HVGO-(S)west-004-0041-1A, (S)East 004-0041-1B. #8 unit Diesel Product 113BB, 113AB, 113BA,113AA. HHPS 114BB,114AB,114BA,114AA

You all done an excellent job on all of the fin fans. It was done safely and in a timely manner. Temp. drop on all of the fin fans. Appreciate all of your work.

Thanks

“….. Everything has gone well. They’ll be finishing up shortly. If we want Al and the crew back tomorrow to hit a couple of more fans…”

Hello (-)

The test with the fin fans here at Nexen Long lake was a success and we would like to schedule you in to clean another 70 Fans.

Can you provide myself and John a quote for this work and we can set a date please?

fin fan air coolers: After the cleaning – outlet temperature reduced by 77-86F (25-30C) and vacuum significantly increased.

Hi (-),

Regarding your visit to Sasol Secunda complex and the work that you guys performed for us, I would like to extend my gratitude for the manner in which you performed your tasks!

- Safety

o I really appreciated it that you were so safety conscious. Seeing that this is completely new to the Sasol environment, your guidance in the safety measures that needed to be put in place was highly appreciated and respected. The task was done safely and even when we had a small hiccup, you quickly made a plan to work more safely.

o You also respected our safety and governance processes and adhered to them.

- Technical

o The tasks were done with a high level of professionalism. We could see that you really believe in your cleaning method and that you take your job seriously.

o The good results on the heater parameters also indicated the success of the project.

o Your enthusiasm to add value to other units within Sasol was also evident.

- Overall

o Even though it took a while to get you badged and into the plant, you guys always remained friendly and professional. The job was done safely and to a high technical standard. It was a joy to work with you.

All the best and thanks,

To whom it may concern,

The furnace online cleaning (F7101 A/B/C) of both the radiant and convection bank of Crude Distiller 2 and the fin fan bank (E7209) was successfully done from Monday until Saturday.

SENTRO performed this activity with the highest degree of competency and safety. In addition, the housekeeping was excellent.

The final benefit with regards to BWT (bridge wall temperature) is 80 degrees and 25 degrees benefit with regards to stack temperature. The benefit would have been higher if there were more access to the convection bank.

The fin fan bank of E7209’s were cleaned. Prior to the cleaning, the fan pitch was at 100%, the feed rate was at 260 t/d and we were flaring. Soon after the cleaning, the fan pitch was at 20%, the unit feed rate increased to 340t/d and there was no flaring,

Kindest regards

After cleaning: Tubes are clean; refractory (ceramic fiber) is undamaged

Here is what I see on the fuel gas system:

- About 1 psig reduction in fuel gas pressure.

- Fuel gas control valve opening dropped about a 3%

- All the skin temperatures increased which may suggest the heat transfer improved.

- Fuel gas consumption dropped about 2000 scfh

When inspection does an IR scan of the tubes in July it will be interesting if they see a signal on tube temperatures with the IR scan.

Crude Heater 501 – radiant section (LA, USA)

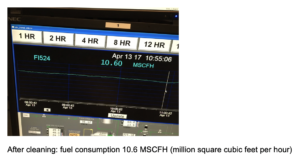

Result: fuel consumption is decreased by 5.4%

Crude Heater 502 – radiant section (LA, USA)

Result: fuel consumption is decreased by 5.9%

Heater 503 – convection section (LA, USA)

Result: North stack temp. is decreased by 51 degrees

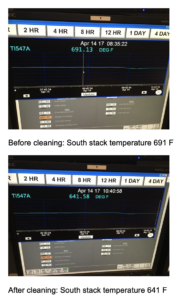

Heater 504 – convection section (LA, USA)

Result: South stack temp. is decreased by 55 degrees

Convection section cleaning (CA, USA)

Radiant section cleaning (KS, USA)

Dirty radiant “shock tubes” before cleaning – fouled, and hot spots

Result: all scale and hot spots have been removed. The thermal efficiency of the heater has been increased.

Ethylene Heater

In approximately April of 2019, I was assigned to find a solution for furnace convection cleaning. We were experiencing high convection section temperatures due to convection section fouling. Traditionally the equipment must be shut down and locked out in order to conduct the cleaning. Through some independent research, we found an online cleaning service, Sentro-Tech. After reaching out to Sentro-Tech we got a very quick response. After a few discussions, we were able to set up a meeting with Sentro-Tech personnel, the environmental, safety, and furnace team. We discussed safety concerns and the environmental impact. After due process and approval, we were given the authorization to do a test run on our worst furnace convection section. During that process, Sentro-Tech was extremely professional with outstanding customer service, and readily provided all information that was necessary to expedite the job. The job was then scheduled (approximately the end of July), with minimal execution required, we were able to complete the convection section cleaning online within 12 hours with no safety incidents at temperatures above 1000F. The results were immediate and measurable online. Without divulging proprietary information, we saw a stack reduction of 50 degrees; which is excellent for the age of that convection section. The annuitized financial impact exceeded expectations. The process and the performance by Sentro-Tech allow the versatility for excellent cleaning of convection sections online, without taking the equipment out of service. This is a truly innovative technology that I highly recommend to anyone looking for similar results. Flint Hills Resources plans to continue using Sentro-Techs services in the future for convection cleaning.

Coker Heater

Just wanted to say THANKS! I know it was slow getting started with the unplanned S/D’s and Weather issues but as you can see from the trends

Below it looks like we dropped 70 degrees after the cleaning. That’s huge! This will allow us to run unconstrained till BBTA 19’

Would it be possible to get a report out from Sentro, nothing elaborate? I foresee us using them routinely at the Coker and other Units here at Deer Park

and outside Deer Park have been waiting to see what type of results we had. I would be sharing their report out with other Units and Sites.

Starting Stack Temp 952.7

Ending Stack Temp 882.7

(CHS McPherson KS) Reduced fuel consumption by 9.1%

(CHS Montana) Reduced stack temperature by 110F

(PAR Hawaii) Reduced fuel consumption by 5.9%

(PAR Hawaii) Reduced stack temperature by 109F