Online (in-process) dry chemical cleaning of heater and boiler tubes (external fire-side of the tube), through non-hazmat SENTROMAXTM dry chemicals, for both radiant and convection sections in furnaces, as well as furnace, superheater and economizer in boilers.

- Conducted “on-the-run” during normal operating conditions with no loss of production

- Flexible scheduling for the cleaning – limited equipment access required

- Immediate measurable results and benefits – visible operational improvements while undergoing cleaning process:

- ✔ Stack temperature reduced

- ✔ Fuel consumption reduced

- ✔ Production rate increased

No damage to tubes, refractory, or instrumentation

- No negative impact on SCR or other NOx reduction systems

- Mechanical and chemical cleaning occur simultaneously, as compared to dry ice or walnut blasting that act mechanically and are low effective methods

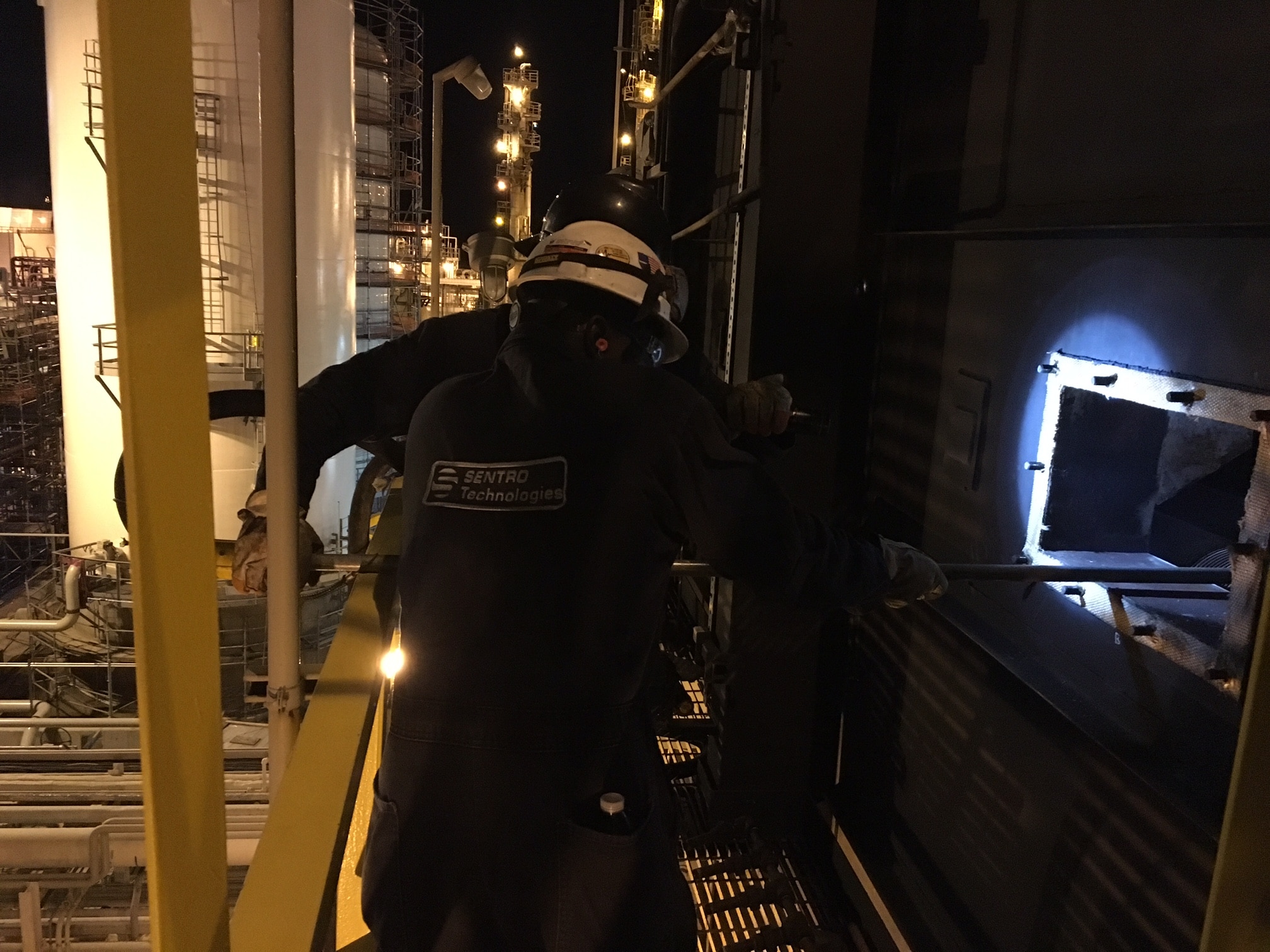

- Little or no scaffolding is required – typical access from existing platforms

- No cleanup required – non-hazmat SENTROMAXTM chemical decomposes into gas and exits heater in flue gas

- Green Solution – No negative environmental impact

- No confined space entry

- Significantly increased accuracy of IR thermographic readings of tubes skin temperature

All SENTRO’s cleaning and inspection systems are the result of practical applications combined with continuous research and development.