Vapor Phase Chemical Cleaning

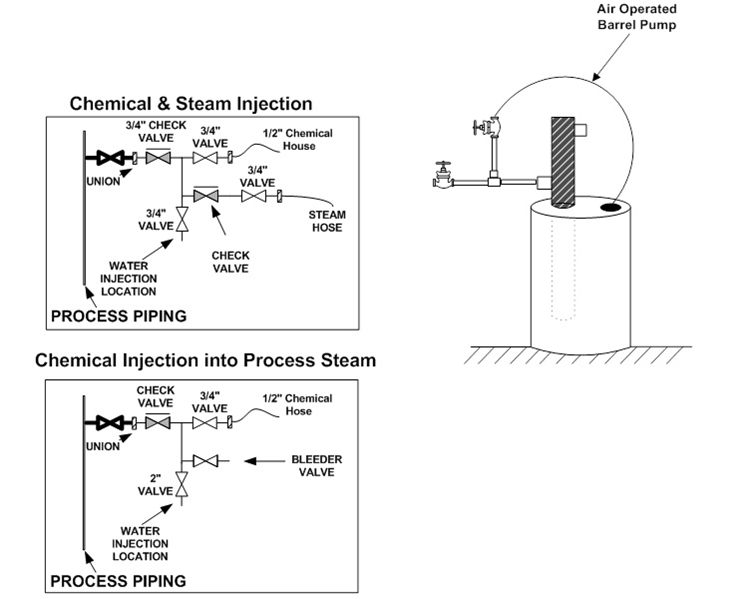

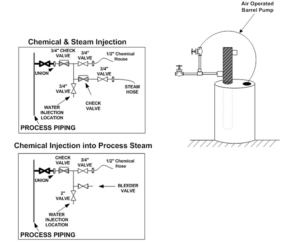

- Fast and inexpensive setup for chemical-steam injection into the equipment, through SENTROKLINTM.

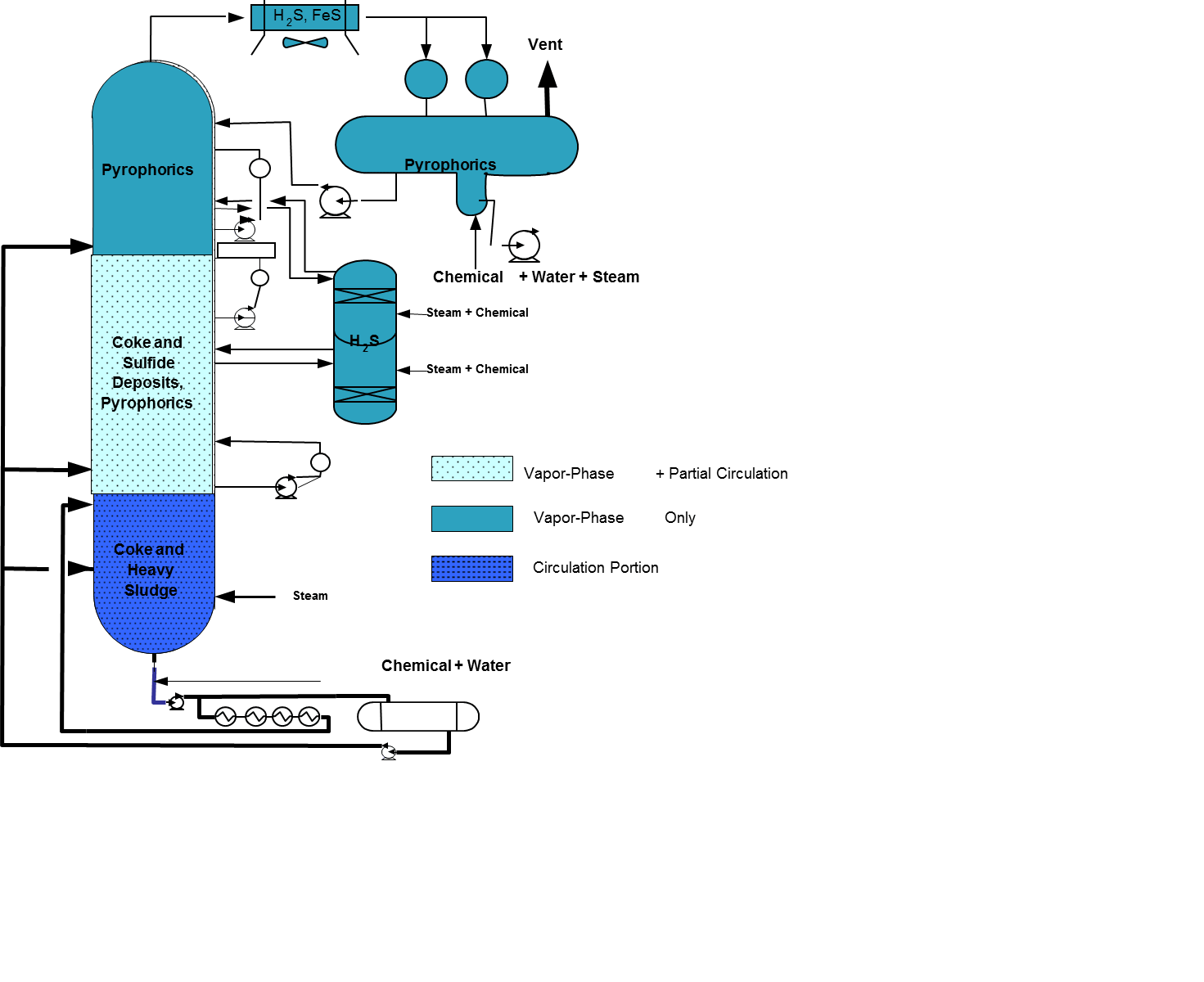

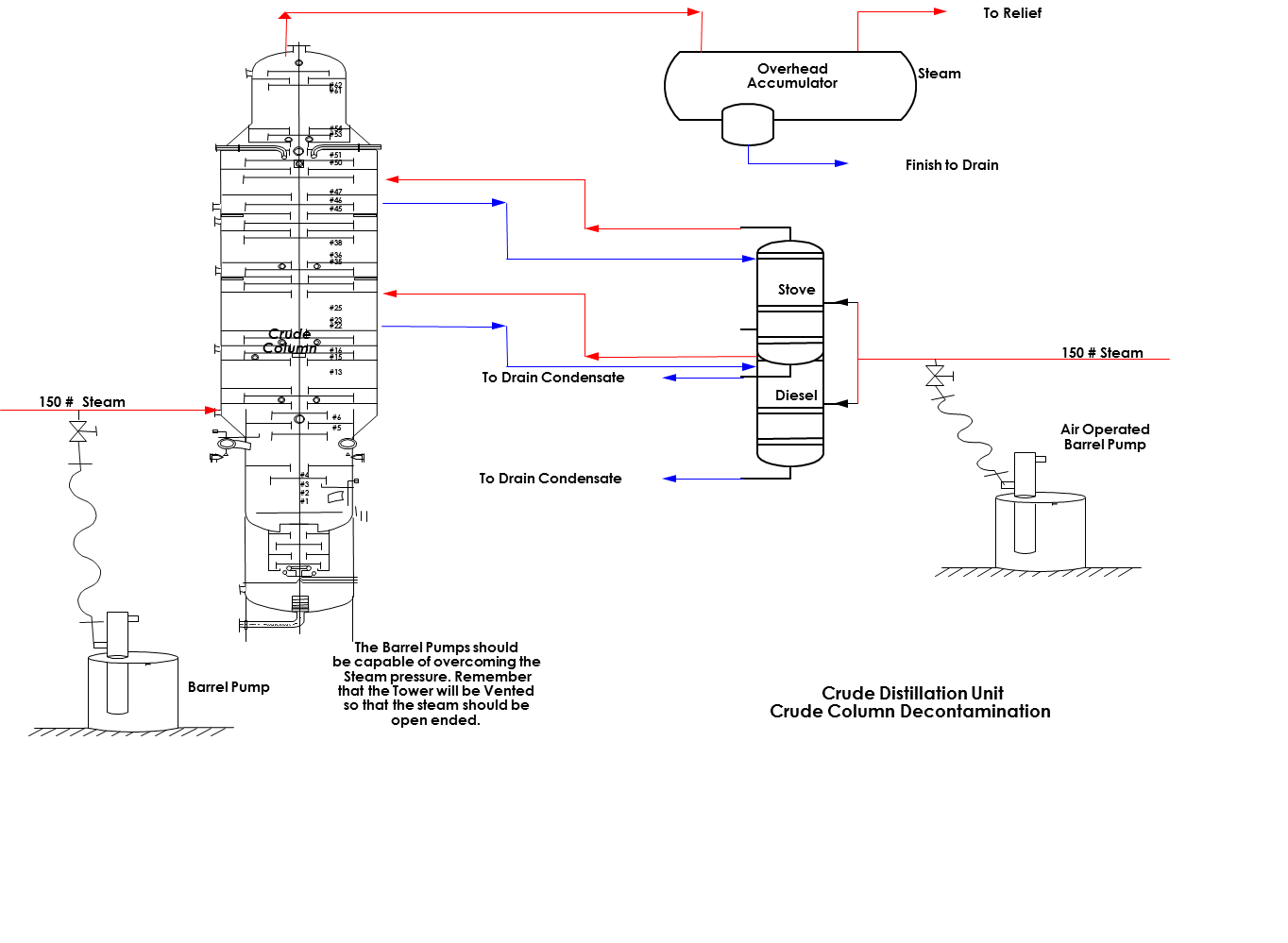

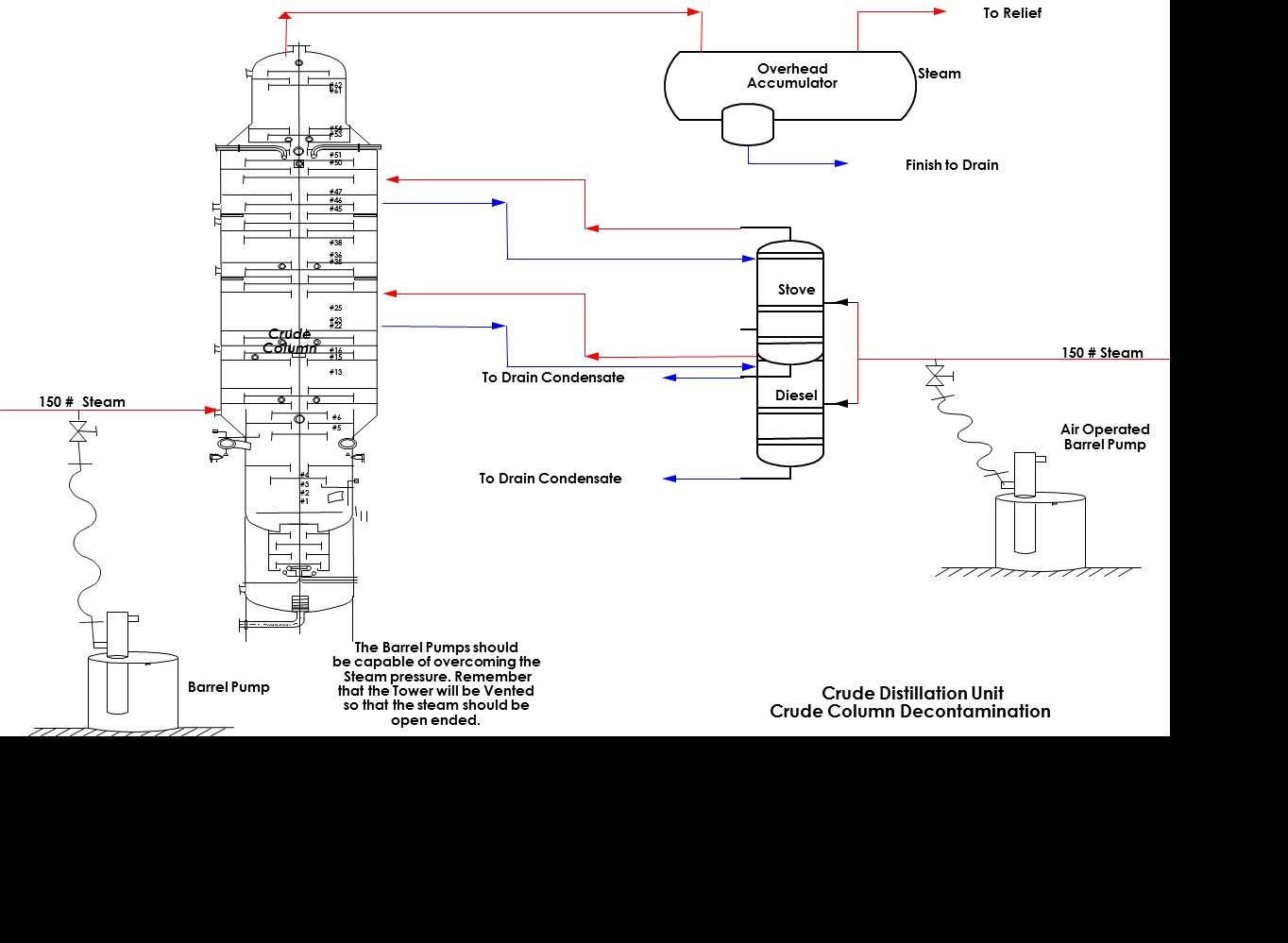

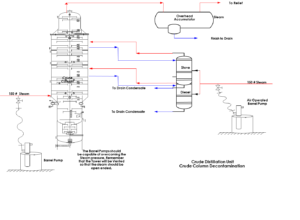

- Applicable for heavy-oil units such as atmospheric, vacuum, coker, FCC, reformer, desalter and more.

- Also applicable for heating or cooling systems, such as furnace, tower bottom, overhead system (coolers, accumulator), pump-around / side-cuts etc.

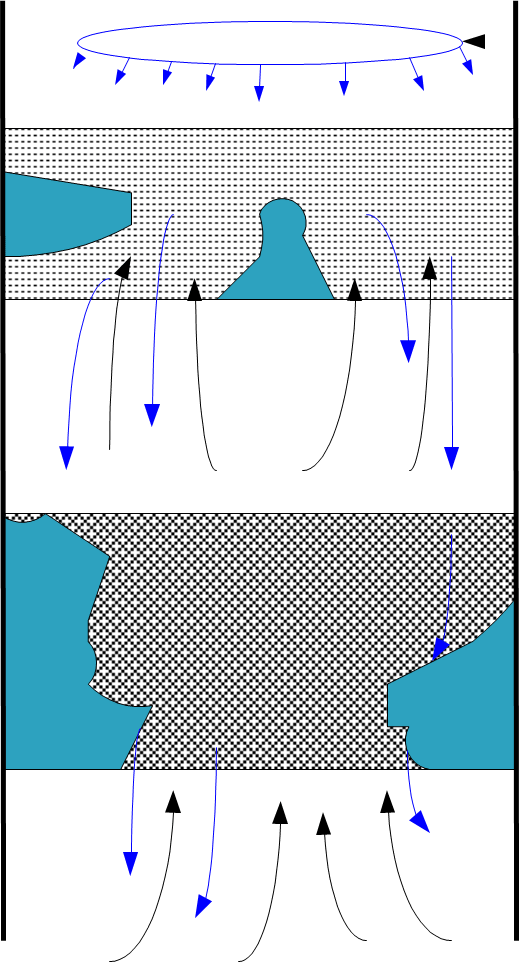

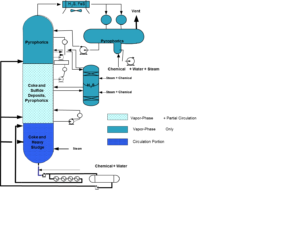

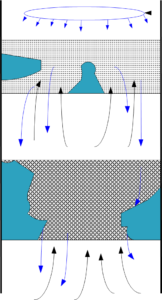

- Our vapor-phase cleaning method is based on continuous injection of fresh chemical, continuous monitoring of hydrocarbon/LEL/H2S/benzene levels, de-oiling, de-gassing, sulfide oxidation (all pyrophoric components are oxidized and get inactive in the cleaning process).

- Down time is minimized by reducing steaming duration and reducing maintenance activities before and after decontamination process

- Environmentally friendly cleaning process, biodegradable and extremely low chemical oxygen demand (COD) waste

- Does not make stable emulsions and minimizes the amount of waste generated

- This cleaning process is effective and efficient: It penetrates and softens heavy residuals and asphaltenes, it assures chemical contact and reduces the possibility of channeling and it suspends coke scale and particulates

- Cleaning results are better than a traditional cascade or full liquid circulation – due to the higher cleaning temperature, with less effluent volume, and fewer mechanical connections and less maintenance time.

All SENTRO’s cleaning and inspection systems are the results of practical applications combined with continuous research and development.

Sentro Technologies USA, LLC

Online Dry Chemical Cleaning of Fin Fan Air Coolers, Furnaces, and Boilers | APR Acoustic Pulse Reflectometry Tube Inspection | Acoustic Emission Testing | Jacob's Sniffer 430 Leak Detection